Mirror Laser Sandblasting Machine Introduction

The Mirror Laser Sandblasting Machine adopts a new high-peak, anti-high-reflection fiber laser source featuring excellent beam quality, high power stability, low energy consumption, and long service life.

It can engrave any patterns or textures on the surface of mirrors, metals, and other materials.

The selected processing software enables automatic large-stroke Z-axis adjustment to ensure high-quality processing of panels with different thicknesses and materials. It also guarantees fewer failure points and high stability during operation. The software is simple and flexible to use — even beginners can master it within about three hours.

The whole machine occupies a small footprint, is easy and safe to operate, and requires no special operator skills — just brief training before use. It delivers fast processing speed, high precision, and reduces labor costs.

Equipped with imported electrical and pneumatic components, the machine offers high cost performance, easy operation, low investment, and high return. It significantly lowers the overall cost of use, making it the best choice for small and medium-sized glass processing enterprises.

Function Overview

Laser sandblasting laser machine is a new type of environmentally friendly and energy-saving deep-processing technology.

This machine integrates four functions in one system — sandblasting, paint removal, bottoms marking, and drilling holes, with quick switching between functions without stopping the machine.

The large-format Smart Mirror Laser Sandblasting Machine replaces the traditional etching process — no masking, coating, or sand spraying is required. It is fast, clean, environmentally friendly, and low-cost, with no consumables or wearing parts. Any pattern can be processed directly from a design file.

The working area is 1.3 m × 2.5 m or 1.5 m × 3 m, with other sizes customizable.

Sandblasting:

Removes the protective paint layer from smart mirrors or back-painted glass in a single pass, achieving a frosted effect. The process is fast, smooth, and does not damage the mirror or glass surface. Whether silver- or copper-coated, the laser produces a fine, uniform matte finish without burrs.

Paint Removal:

Fast and efficient removal of silver, aluminum, copper, and enamel coatings without any chemical reagents. The surface remains clean, bright, and sharp-edged after processing.

Bottoms marking:

High-speed and high-precision engraving with delicate, detailed patterns.

Drilling hole :

Non-contact laser drilling with no consumables; edge chipping is controlled within just a few tens of microns.

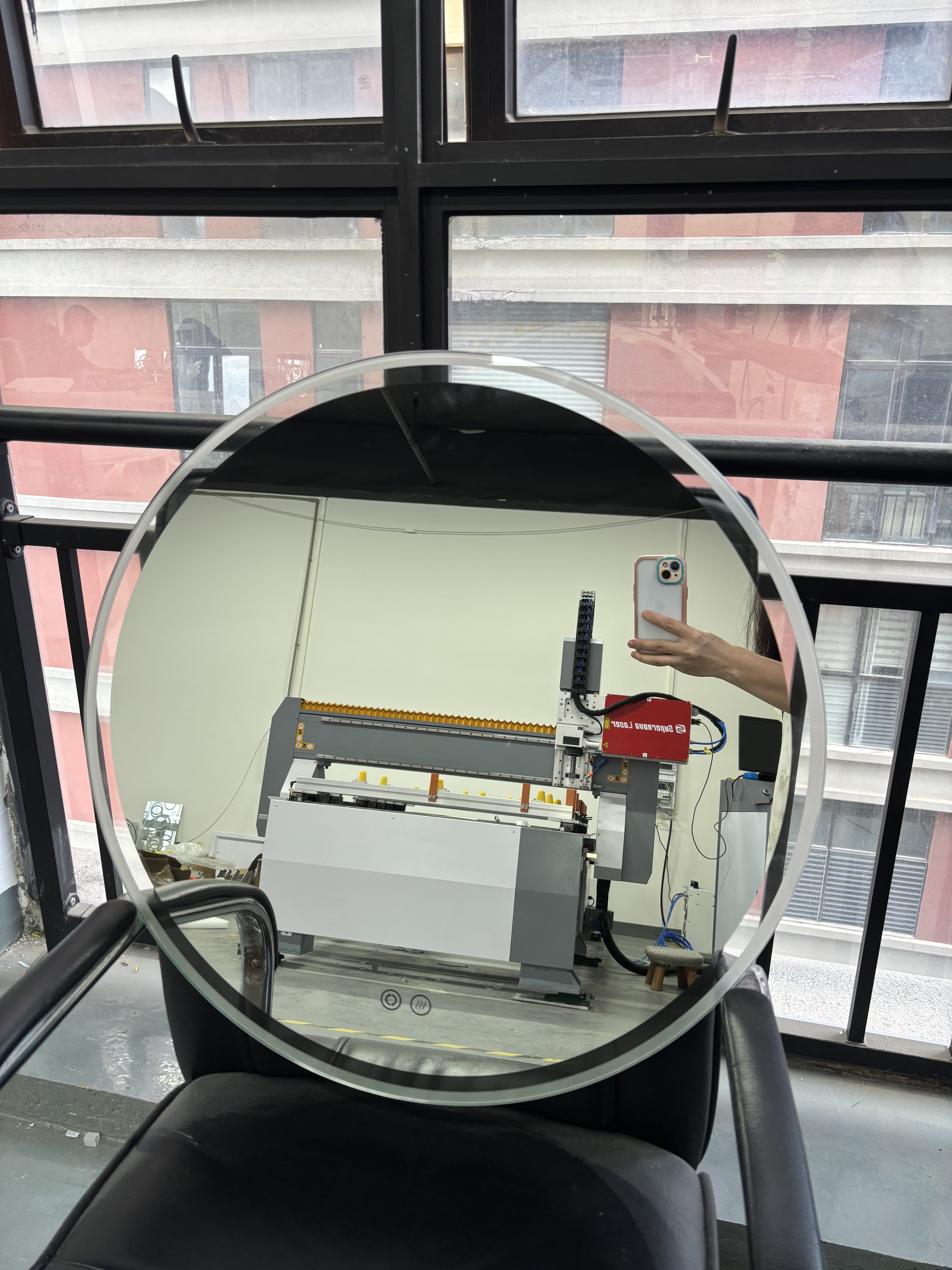

Samples

Reviews

There are no reviews yet.